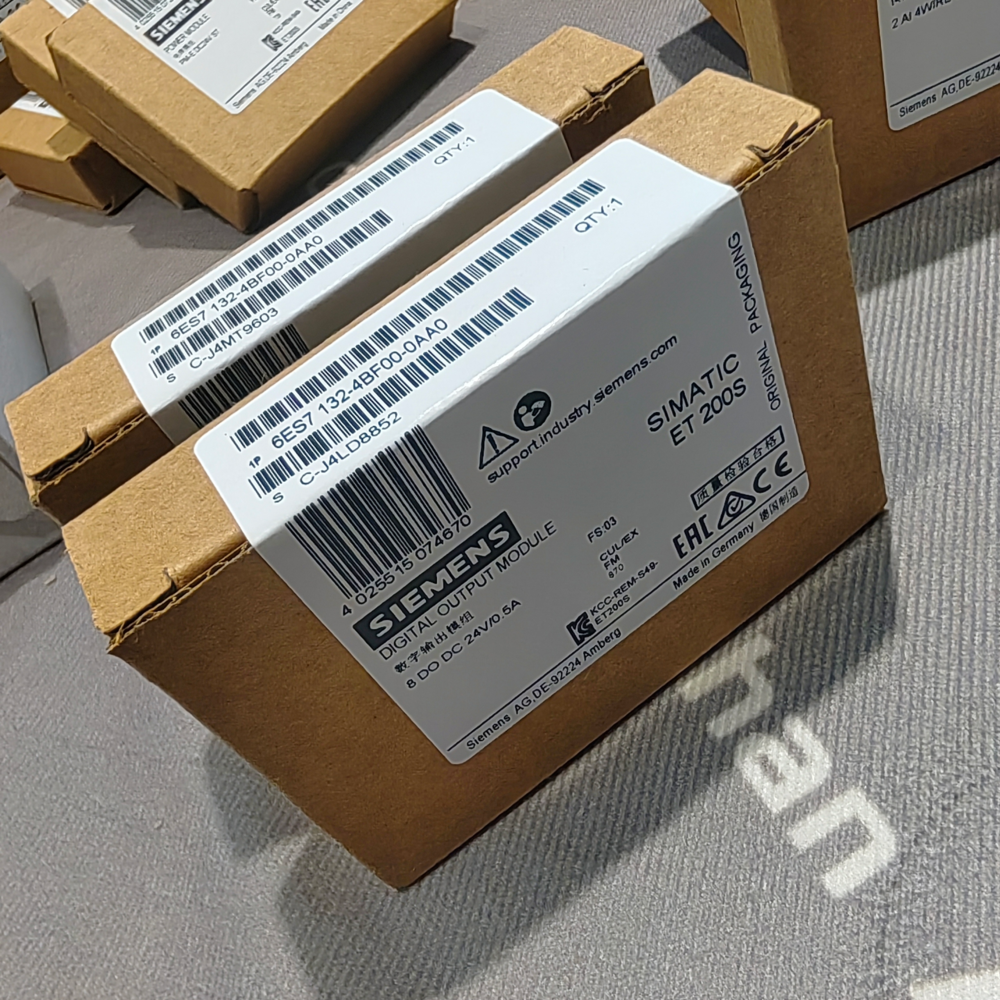

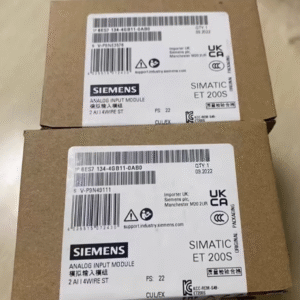

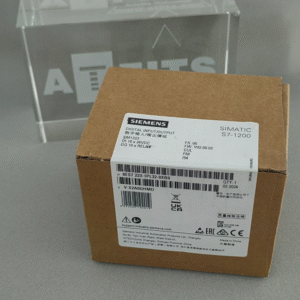

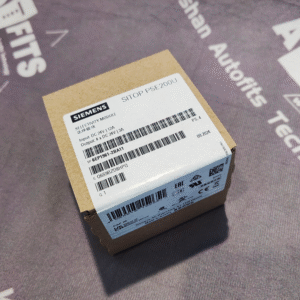

Siemens 6ES7 132-4BF00-0AA0 Digital Output Module: An Overview

The Siemens 6ES7 132-4BF00-0AA0 is a specific component within the SIMATIC ET 200S distributed I/O system, widely utilized in industrial automation applications. This module is designed to interface the control system, typically a PLC (Programmable Logic Controller), with external field devices.

Key Features and Specifications

This particular part number designates a Digital Output (DO) electronic module. Its primary function is to receive digital commands from the controller and output corresponding electrical signals to actuate devices like contactors, indicator lamps, or solenoid valves.

-

Module Type: Digital Output (DO)

-

System: SIMATIC ET 200S

-

Outputs: It typically provides 8 outputs. The “8” often corresponds to the “132” portion of the number sequence in the larger Siemens part catalog system.

-

Voltage and Current: The outputs are designed for a standard industrial voltage, usually 24 V DC. They are sink- or source-switching, depending on the specific backplane or terminal block configuration, and offer a specific rated load current per channel.

-

Connections: The module requires a terminal block (often sold separately) to connect the field wiring (the wires leading to the actual devices it controls).

-

Functionality: It features basic diagnostic capabilities, such as short-circuit protection and potentially LED indicators for channel status.

Role in the ET 200S System

The ET 200S is a modular, decentralized I/O system. The 6ES7 132-4BF00-0AA0 module plugs into an interface module and a power module, which are connected via a bus system (like PROFIBUS or PROFINET) to the central PLC. This decentralized approach allows for I/O points to be located close to the sensors and actuators on the factory floor, significantly reducing wiring complexity and installation costs.

Summary

In essence, the 6ES7 132-4BF00-0AA0 is a reliable, 8-channel, 24 V DC Digital Output module integral to the Siemens ET 200S distributed I/O architecture. It serves as the crucial link between the control logic and the physical machinery, translating software commands into tangible actions in the automated process.

About us