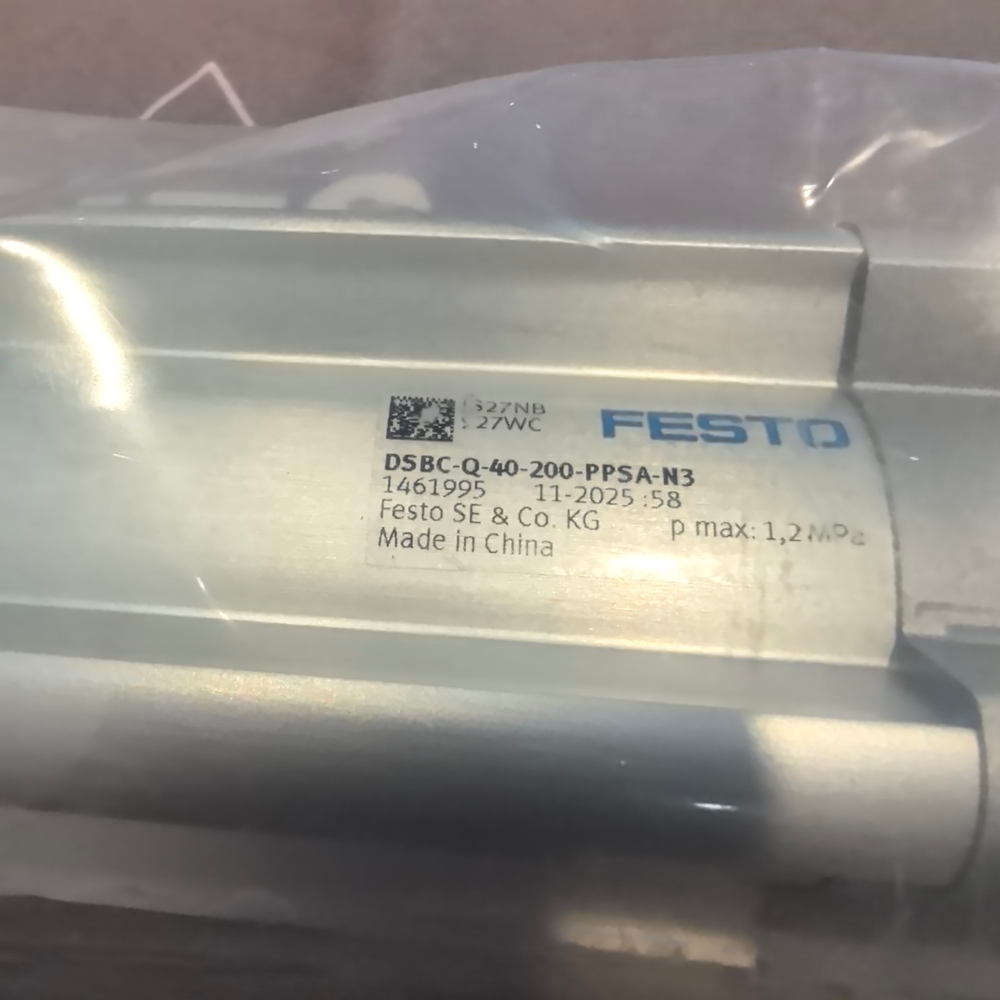

Festo DSBC-40-200-PPSA-N3 ISO Cylinder (Order Number: 1461995)

Product Overview

Main Functions

- Double-acting Linear Actuation

As a double-acting cylinder, it generates force and motion in both the extension and retraction strokes. Compressed air supplied to the cap end port drives the piston rod forward, while air supplied to the rod end port retracts the rod, enabling bidirectional control of mechanical loads.

- Self-adjusting Pneumatic Cushioning

The integrated PPSA (pneumatic self-adjusting cushioning) system automatically adapts to varying loads and speeds, effectively dampening the piston at the end of both strokes. This eliminates impact shocks, reduces noise levels, and protects the cylinder and connected components from premature wear.

- High-precision Positioning

The cylinder’s rigid barrel and precisely machined piston ensure minimal radial play and consistent stroke accuracy, making it suitable for applications that require repeatable positioning of workpieces or tools.

- Load Handling Versatility

With a bore size of 40 mm and a stroke length of 200 mm, it can deliver substantial pushing and pulling forces, accommodating a broad range of load weights and process requirements in industrial settings.

- Easy Integration and Maintenance

Its ISO 15552-compliant mounting interfaces (including front flange, rear flange, and foot mounting options) allow for flexible installation. The cylinder’s modular design also simplifies disassembly and component replacement during maintenance, reducing downtime.

Technical Characteristics

| Technical Parameter | Specification |

|---|---|

| Cylinder Type | Double-acting, ISO 15552 standard |

| Bore Size | 40 mm |

| Stroke Length | 200 mm |

| Cushioning System | Pneumatic self-adjusting (PPSA) on both ends |

| Operating Pressure Range | 0.6 – 10 bar (0.06 – 1.0 MPa) |

| Max. Permissible Pressure | 12 bar (1.2 MPa) |

| Operating Temperature Range | -20 °C to 80 °C (with standard seals; temperature range varies with special seals) |

| Piston Rod Surface | Hard chrome-plated steel |

| Piston Seal | Nitrile butadiene rubber (NBR) |

| Cylinder Barrel Material | Aluminum alloy, anodized |

| End Cap Material | Aluminum alloy |

| Mounting Type Compatibility | ISO 15552 flange, foot, and trunnion mounting |

| Rod Thread Size | M12 x 1.25 |

| Force Output (at 6 bar) | Push force: 754 N; Pull force: 631 N |

| Force Output (at 10 bar) | Push force: 1257 N; Pull force: 1052 N |

| Dynamic Seal Leakage | ≤ 0.5 cm³/min (per ISO 15552) |

| Corrosion Resistance | CRC 2 (medium corrosion resistance) |

| Compliance Standards | ISO 15552, RoHS |

Product Dimensions and Weight

| Parameter | Specification |

|---|---|

| Overall Length (retracted state) | 365 mm |

| Overall Length (extended state) | 565 mm |

| Cylinder Barrel Outer Diameter | 40 mm |

| Piston Rod Diameter | 16 mm |

| Rod End Thread Length | 25 mm |

| Mounting Hole Spacing (rear flange) | 65 mm (center-to-center) |

| Net Weight | 1.8 kg |

| Gross Weight (with packaging) | 2.2 kg |

Structural Highlights

- Hard Chrome-plated Piston Rod

The piston rod’s hard chrome plating provides excellent resistance to abrasion, corrosion, and scuffing, ensuring smooth motion and long service life even in dusty or humid environments.

- Anodized Barrel

The anodized aluminum alloy barrel offers high strength-to-weight ratio and corrosion protection, while its smooth inner surface reduces friction between the piston and barrel, optimizing motion efficiency.

- Self-adjusting Cushioning

Unlike fixed cushioning systems, the PPSA mechanism adjusts cushioning force dynamically based on load and speed, eliminating the need for manual adjustment and ensuring optimal damping performance across varying operating conditions.

- Modular Seal Design

The cylinder uses standardized NBR seals that are easy to replace, and optional high-temperature or chemical-resistant seals are available for specialized applications, enhancing the cylinder’s adaptability.

About us