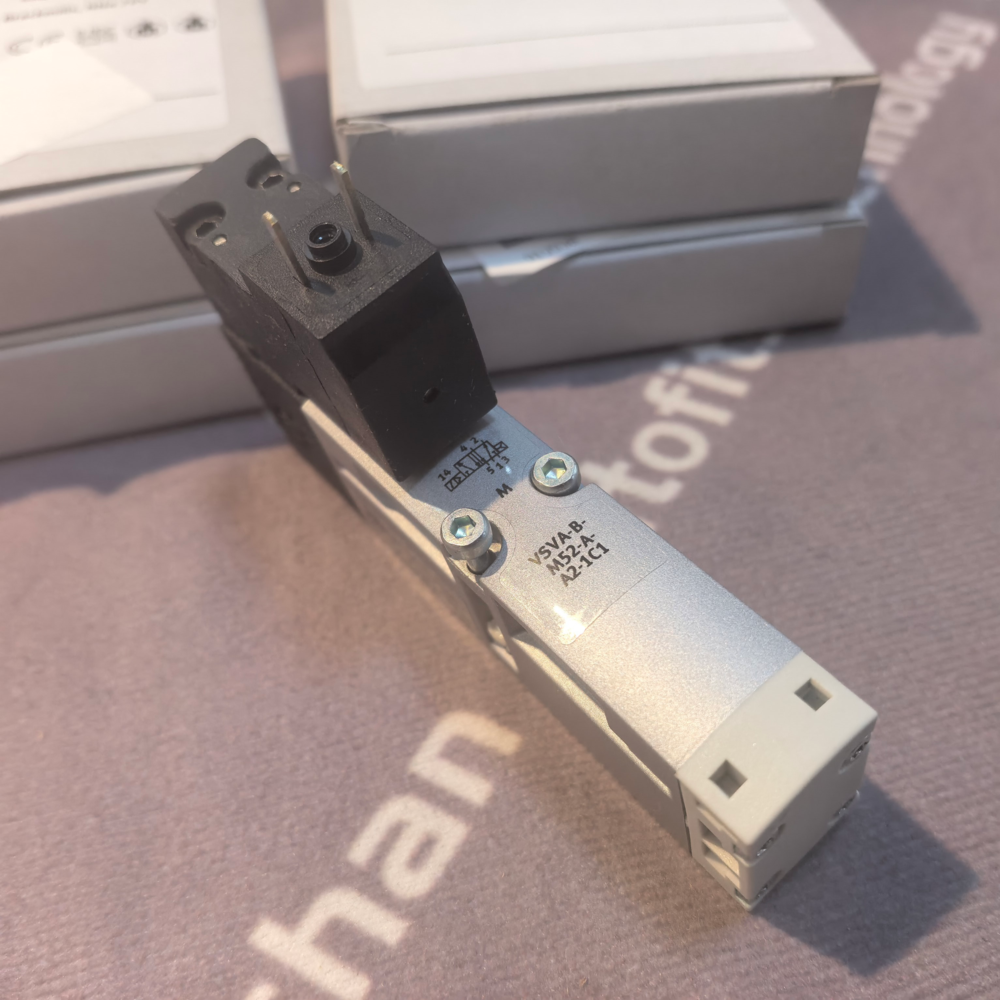

Festo VSVA-B-M52-A-A2-1C1 Solenoid Valve (Order No. 546691)

1. Product Overview

2. Main Functions

| Function | Detailed Description |

|---|---|

| 5/2-Way Pneumatic Direction Control | Precisely switches compressed air flow between two working positions to drive bidirectional motion of pneumatic actuators (e.g., extend/retract cylinders, open/close grippers), enabling cyclic and sequential automation with high repeatability. |

| Bistable Double Solenoid Operation | Dual 24 V AC solenoids enable position locking: the valve switches when one solenoid is energized and remains in that position until the opposing solenoid is activated—no continuous power required, reducing energy consumption and ensuring position holding during temporary power loss. |

| Ultra-Fast Response Actuation | Optimized internal spool and flow channel geometry deliver rapid switching times, enabling fast actuation of pneumatic components and improving the cycle efficiency of high-speed automation lines. |

| Lubrication-Free Operation | Fully compatible with dry, filtered compressed air (per ISO 8573-1:2010 [7:4:4]), eliminating the need for oil lubrication and avoiding contamination—ideal for clean applications (electronics, food processing, surface treatment). |

| Low-Leakage Airtight Performance | High-precision FKM/NBR seals and machined spool/valve body mating surfaces minimize air leakage, reducing compressed air waste, lowering energy costs, and maintaining stable system pressure for reliable actuator control. |

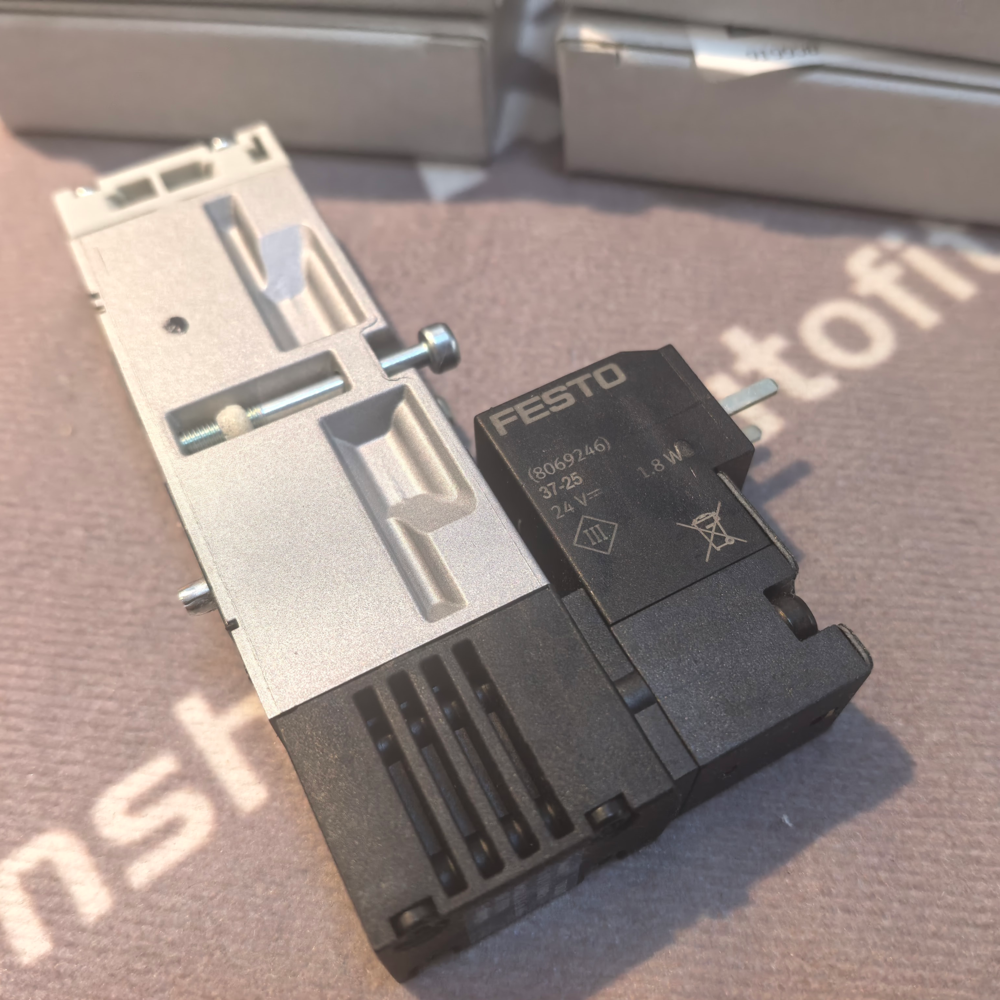

| Modular Manifold Compatibility | Seamlessly integrates with Festo VSVA series valve manifolds, enabling centralized installation of multiple valves to save space, simplify piping/wiring, and streamline maintenance and system expansion. |

| Corrosion-Resistant Industrial Operation | Robust material construction (anodized aluminum, stainless steel) resists mild industrial corrosion, dust, and moisture, ensuring consistent performance in factory environments with variable operating conditions. |

| Standardized Universal Integration | Equipped with standardized G1/4 pneumatic ports and M12×1 5-pin electrical connectors, ensuring full compatibility with Festo’s pneumatic components (actuators, fittings, sensors) and other industrial standard automation equipment. |

3. Technical Features

- Compact Modular Slim Design

Ultra-small installation footprint (45×28×95 mm) with a slim valve body, suitable for decentralized mounting on actuators or centralized integration on dense control panels—ideal for space-constrained automation setups.

- Energy-Efficient Bistable Operation

Double solenoid actuation without return spring: no continuous power supply for position holding, reducing idle power consumption and providing fail-safe position locking for critical automation tasks.

- High-Durability Material Construction

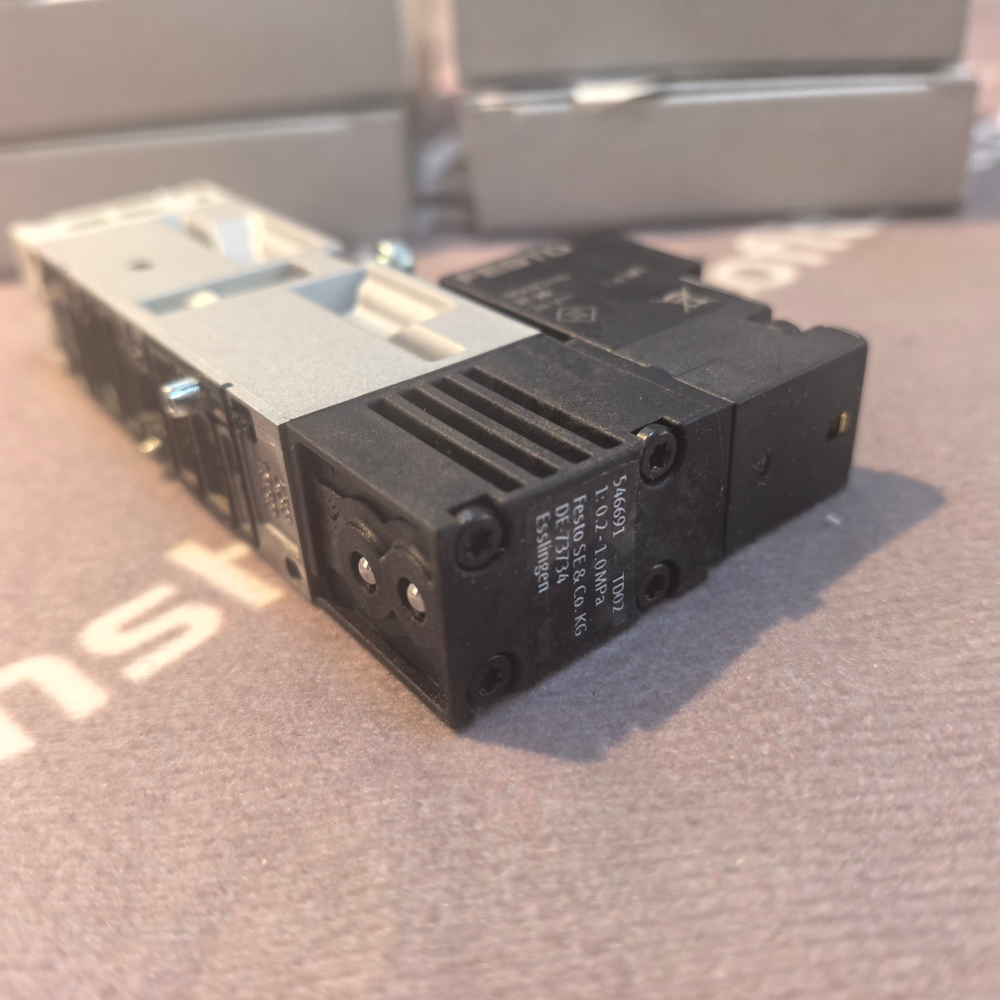

Anodized wrought aluminum alloy valve body (lightweight, corrosion-resistant); stainless steel (1.4301) spool/shafts (wear/scratch-resistant); high-performance FKM/NBR elastomer seals (long-lasting airtightness, low leakage).

- Wide Operational Range

Operates at an inlet pressure range of 0.8–10 bar (0.08–1.0 MPa) and ambient temperature range of -10°C to +50°C (no condensation), compatible with standard industrial compressed air systems and diverse factory environments.

- IP65 Ingress Protection

Solenoid and electrical connection section feature IP65 protection, resisting dust ingress and low-pressure water jets from all directions—ensuring reliable operation in harsh, wet/dirty industrial conditions.

- PWIS & RoHS Compliance

Free of Paint Wetting Impairment Substances (PWIS, VDMA 24364), safe for automotive painting and surface treatment processes; RoHS compliant for environmental compatibility and global industrial use.

- Tool-Free Maintenance & Replacement

Solenoid coils can be replaced without special tools; standardized pneumatic/electrical interfaces simplify on-site installation, repair, and component replacement—minimizing unplanned downtime.

- High Flow Capacity with Low Leakage

Optimized internal flow geometry delivers a Cv value of 0.8 (sufficient for medium/large pneumatic actuators) with a leakage rate of ≤0.5 l/min (at 6 bar)—balancing high flow efficiency and energy savings.

- High Repeatability Switching

Tight manufacturing tolerances and precision-machined internal components ensure consistent switching performance and high positional repeatability, critical for high-precision assembly and positioning tasks.

4. Product Dimensions (Unit: mm)

| Dimension Parameter | Value |

|---|---|

| Overall Valve Body Length | 45 |

| Overall Valve Body Width | 28 |

| Overall Height (Incl. Solenoid Coils) | 95 |

| Valve Body Thickness | 18 |

| Pneumatic Port Type | G1/4 (BSPP) |

| Pneumatic Port Inner Diameter | 13.16 |

| Mounting Hole Diameter | 4.5 |

| Mounting Hole Spacing (Center-to-Center) | 30 × 20 |

| Single Solenoid Coil Diameter | 25 |

| Single Solenoid Coil Length | 35 |

| Electrical Connection Port | M12 × 1 (5-pin male) |

| Manifold Mounting Interface | Festo VSVA Series Standard |

5. Weight and Material Specifications

| Component | Material | Weight (g) |

|---|---|---|

| Valve Body | Anodized Wrought Aluminum Alloy | 120 |

| Double Solenoid Coils (24 V AC) | Copper Wire + Heat-Resistant PA Plastic Shell | 85 |

| Spool & Internal Shafts | Stainless Steel (1.4301) | 30 |

| Seals & O-Rings | FKM + NBR High-Performance Elastomers | 10 |

| Mounting Fasteners/Clips | Zinc-Plated Steel (Corrosion-Resistant) | 15 |

| Pneumatic Port Inserts | Nickel-Plated Brass | 25 |

| Electrical Connector Housing | Nylon Plastic (Impact-Resistant) | 5 |

| Total Weight (Complete Assembly) | – | 290 |

6. Key Performance Parameters

| Parameter | Value |

|---|---|

| Valve Type | 5/2-Way Directional Control Solenoid Valve |

| Order Number | 546691 |

| Operation Mode | Bistable (Double Solenoid, No Return Spring) |

| Actuation Voltage | 24 V AC |

| Nominal Power Consumption | 5 W per solenoid coil |

| Operating Pressure Range | 0.8 – 10 bar (0.08 – 1.0 MPa) |

| Flow Capacity (Cv Value) | 0.8 |

| Leakage Rate | ≤0.5 l/min (at 6 bar, exhaust port) |

| Ambient Temperature Range | -10°C to +50°C (No Condensation) |

| Working Medium | Filtered Compressed Air (ISO 8573-1:2010 [7:4:4]) |

| Lubrication Requirement | None (Lubrication-Free Compatible) |

| Pneumatic Port Type | G1/4 (BSPP) |

| Electrical Connection | M12 × 1, 5-pin male connector |

| Ingress Protection Rating | IP65 (Solenoid/Electrical Section) |

| Corrosion Resistance Class | CRC 2 (Moderate Corrosion Stress) |

| PWIS Compliance | Yes (VDMA 24364) |

| RoHS Compliance | Yes |

| Manifold Compatibility | Festo VSVA Series Valve Manifolds |

| Mounting Options | Direct Mounting / Manifold Mounting |

Sobre nosotros