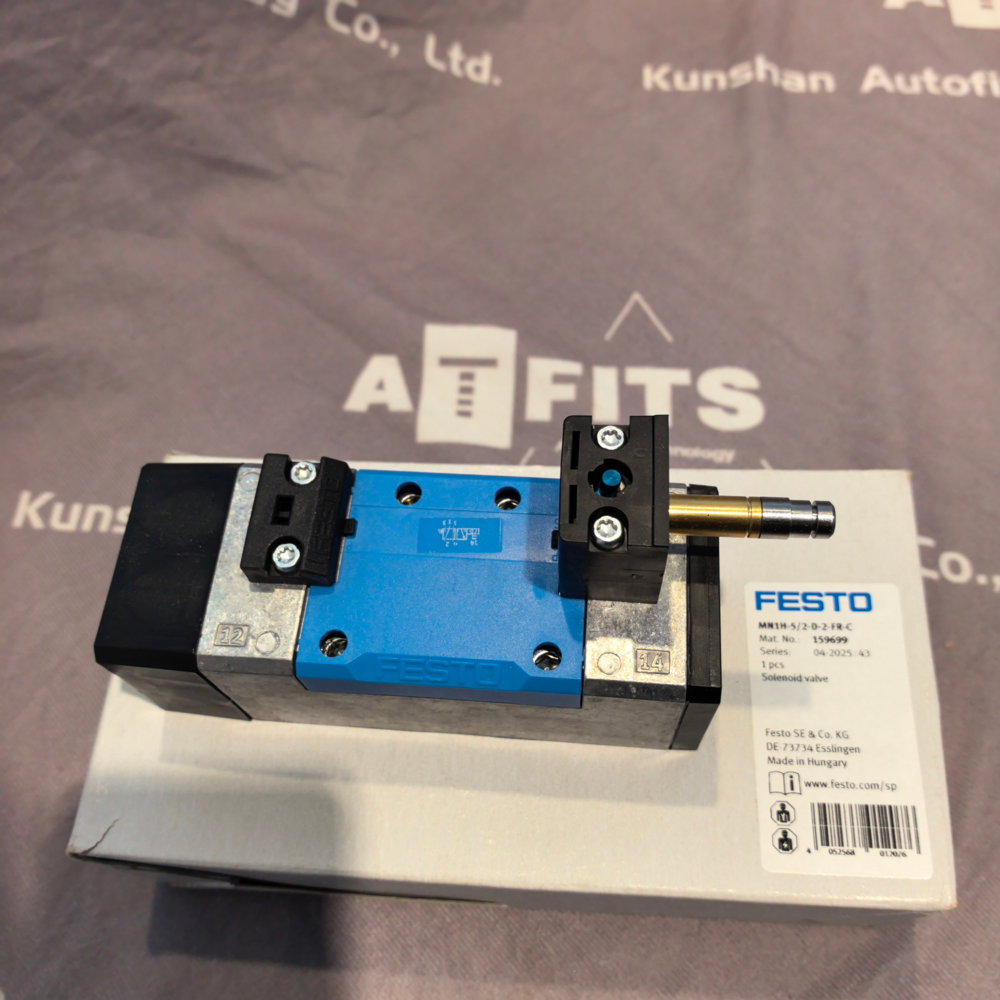

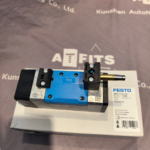

Festo MN1H-5/2-D-2-FR-C Air solenoid valve 159699

"*" señala los campos obligatorios

Festo MN1H-5/2-D-2-FR-C Air Solenoid Valve (Order Number: 159699)

Product Overview

Main Functions

- 5/2-Way Bistable Directional Control

As a 5/2-way valve, it manages air flow between one inlet port (1), two working ports (2, 4), and two exhaust ports (3, 5). The bistable double-solenoid design allows the valve to switch and lock into either of two positions without continuous power supply—energizing solenoid A shifts the valve to connect port 1 to port 2 and vent port 4 to port 5; energizing solenoid B shifts it to connect port 1 to port 4 and vent port 2 to port 3. This ensures energy efficiency and fail-safe position retention during power outages.

- High-Flow Air Delivery

Optimized internal flow channels enable a large nominal flow rate, supporting rapid actuation of large-bore cylinders and high-volume pneumatic devices, which shortens machine cycle times and boosts operational efficiency.

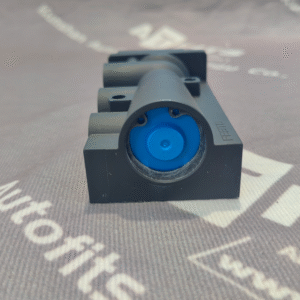

- Tool-Free Push-In Pneumatic Connection

The FR-type push-in locking connections allow quick, tool-free assembly of pneumatic tubing, reducing installation time and eliminating the risk of thread damage associated with traditional threaded connections.

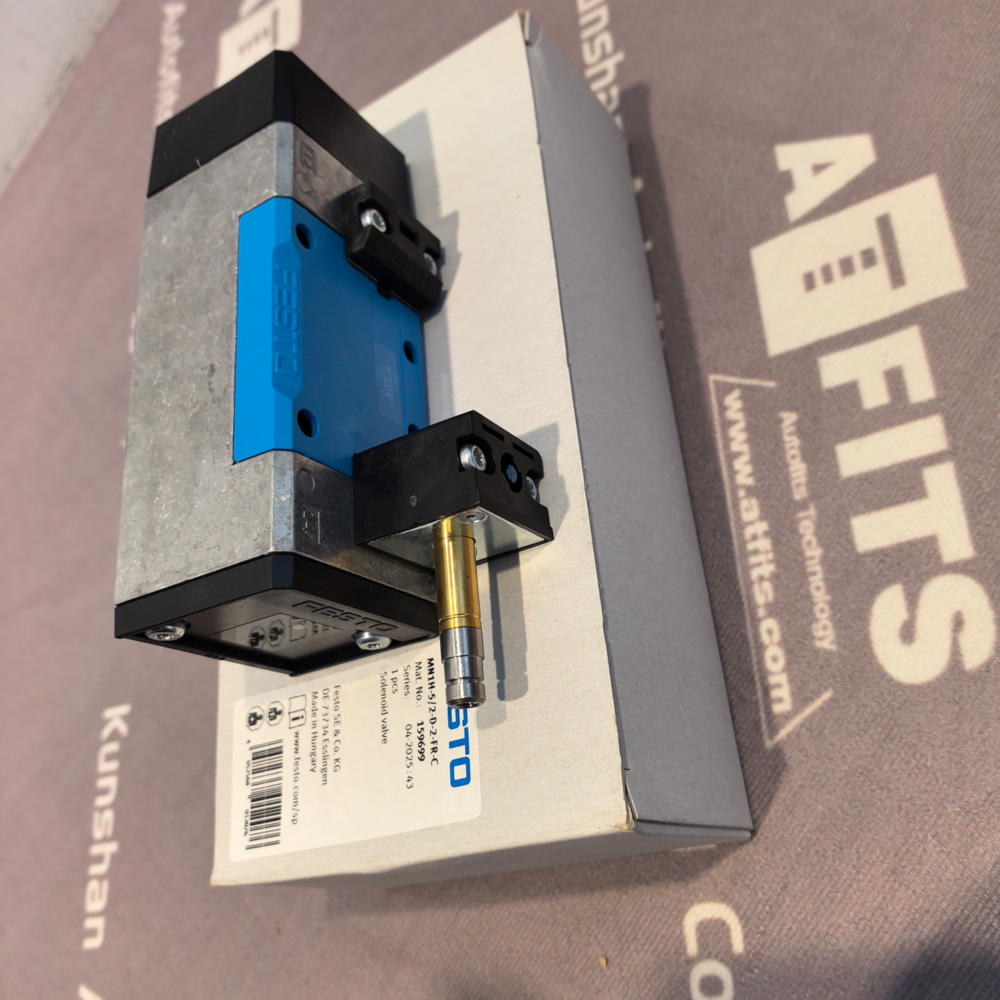

- Manual Override for Maintenance

Equipped with lockable manual override buttons on both solenoid sides, the valve can be manually actuated for system commissioning, leak testing, or emergency operation when electrical power is unavailable. The lockable design prevents accidental position shifts during maintenance.

- Wide Pressure Range Adaptability

It operates across a broad pressure spectrum, making it suitable for both low-pressure control tasks and high-pressure heavy-load applications, with strong compatibility for different industrial pneumatic systems.

Technical Characteristics

| Technical Parameter | Specification |

|---|---|

| Valve Type | 5/2-way, double-solenoid, bistable |

| Actuation Principle | Solenoid actuation with springless bistable locking |

| Nominal Flow Rate (DIN 1343) | 6000 l/min |

| Operating Pressure Range | 1.5 – 10 bar (0.15 – 1.0 MPa) |

| Maximum Permissible Pressure | 12 bar (1.2 MPa) |

| Pneumatic Connection Type | Push-in locking (FR-C) |

| Pneumatic Port Size | G1/2 |

| Electrical Connection Type | DIN 43650 A, form A (connector not included) |

| Solenoid Voltage | 24 V DC (standard); voltage tolerance ±10% |

| Power Consumption | 10 W per solenoid (inrush), 3 W per solenoid (holding) |

| Protection Class | IP65 (per IEC 60529) |

| Operating Medium | Compressed air (ISO 8573-1:2010 [7:4:4]); lubricated or non-lubricated |

| Operating Temperature Range | -10 °C to 50 °C |

| Sealing Material | Nitrile butadiene rubber (NBR) |

| Housing Material | Die-cast aluminum (painted) |

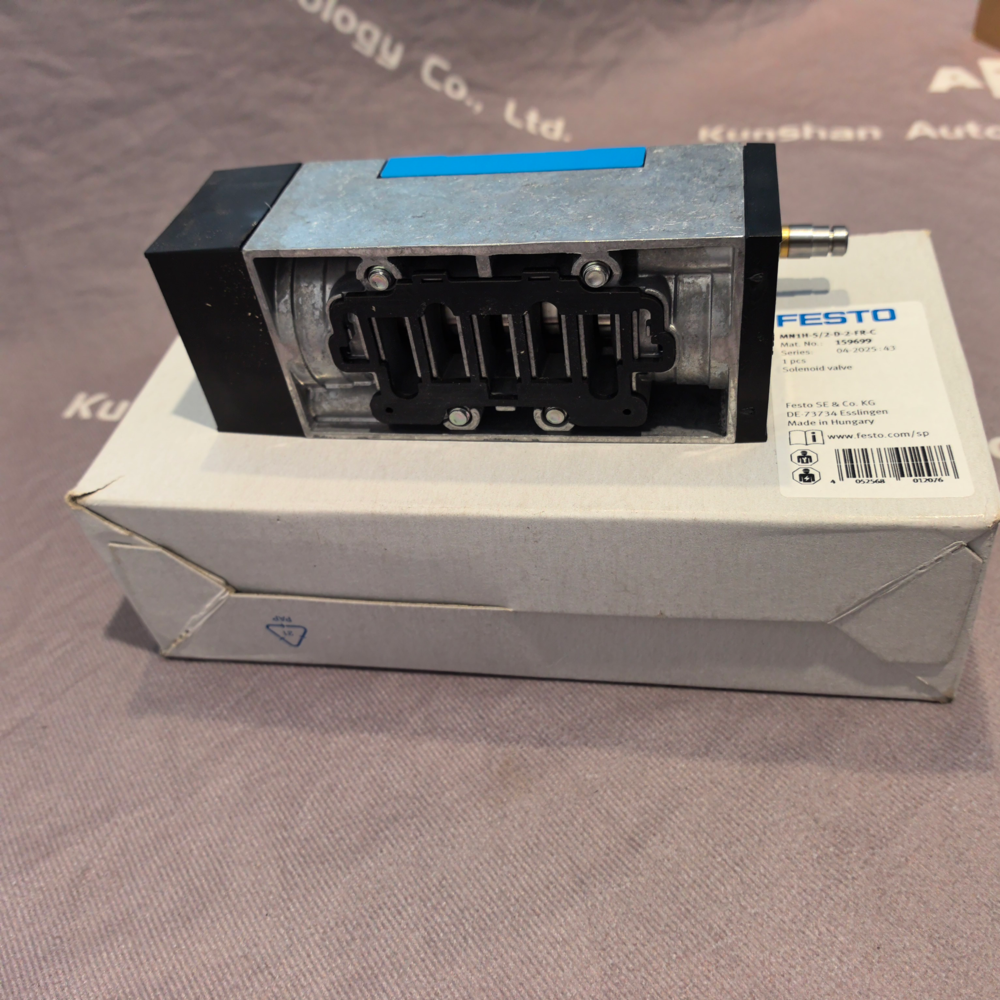

| Mounting Type | Base mounting (compatible with Festo valve bases) |

| Approvals | cULus Recognized, RoHS compliant |

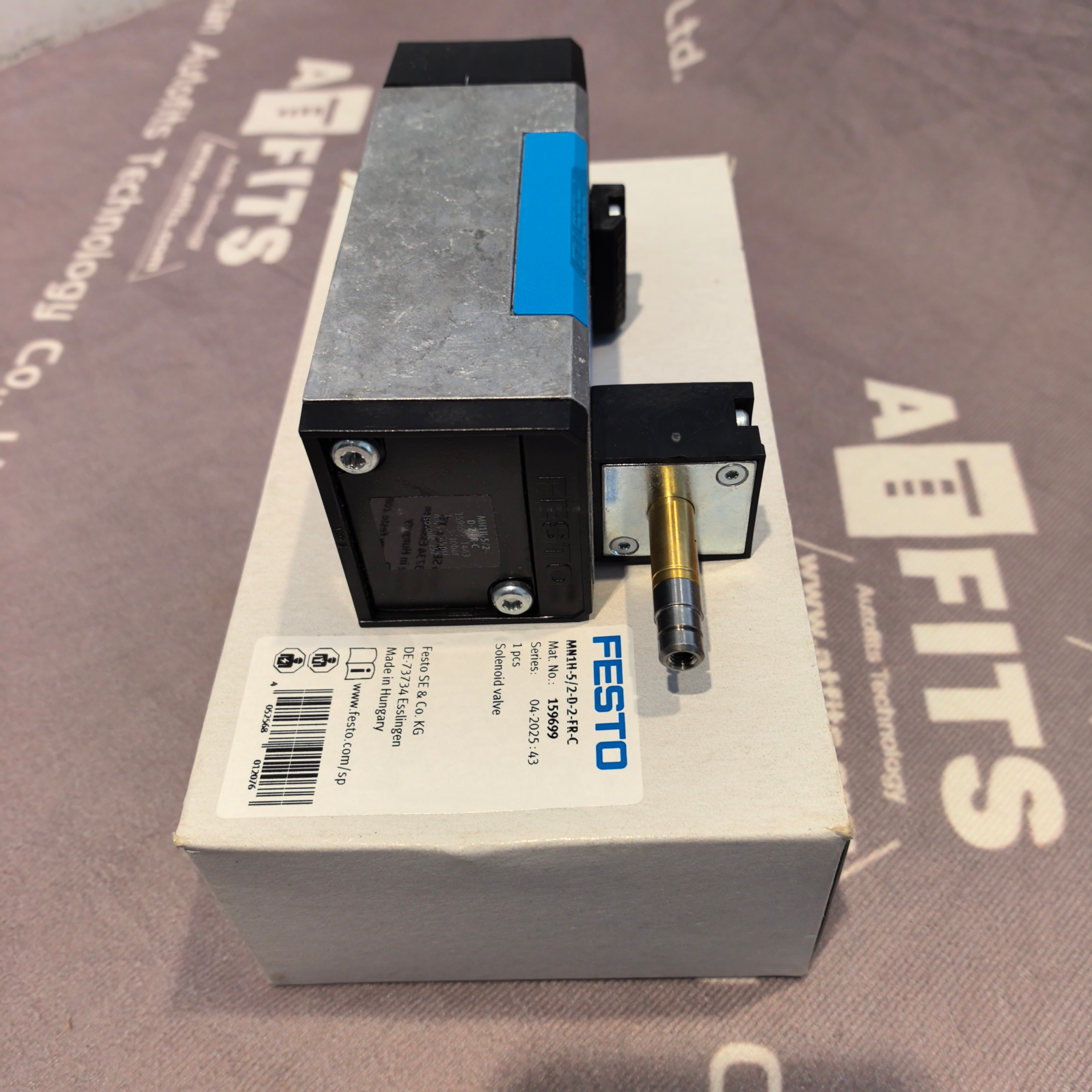

Product Dimensions and Weight

| Parameter | Specification |

|---|---|

| Overall Length | 140 mm |

| Overall Width | 60 mm |

| Overall Height (including solenoids) | 155 mm |

| Pneumatic Port Inlet/Outlet Spacing | 40 mm (center-to-center) |

| Mounting Hole Diameter | 8.5 mm |

| Mounting Hole Spacing | 110 mm (center-to-center) |

| Net Weight (valve with solenoids) | 1.8 kg |

| Gross Weight (with packaging) | 2.5 kg |

Structural Highlights

- Bistable Springless Design

The valve uses a mechanical locking mechanism instead of springs to maintain position, reducing internal wear and extending service life, while also cutting down on energy consumption by eliminating the need for continuous solenoid power.

- Robust Die-Cast Aluminum Housing

The painted die-cast aluminum housing provides excellent mechanical strength, corrosion resistance, and impact resistance, making the valve suitable for dusty, humid, and vibration-intensive industrial environments.

- Optimized Internal Flow Path

The streamlined internal valve core and flow channels minimize pressure loss, ensuring maximum air flow efficiency and rapid response for large pneumatic actuators.

- Push-In Locking Connections

The FR-C push-in ports enable secure, tool-free tubing installation and removal, with a locking mechanism that prevents accidental disconnection even under high vibration.

- Isolated Solenoid Compartments

Solenoids are housed in sealed, isolated compartments to protect internal electrical components from dust and moisture, ensuring stable operation and complying with the IP65 protection class standard.

Sobre nosotros