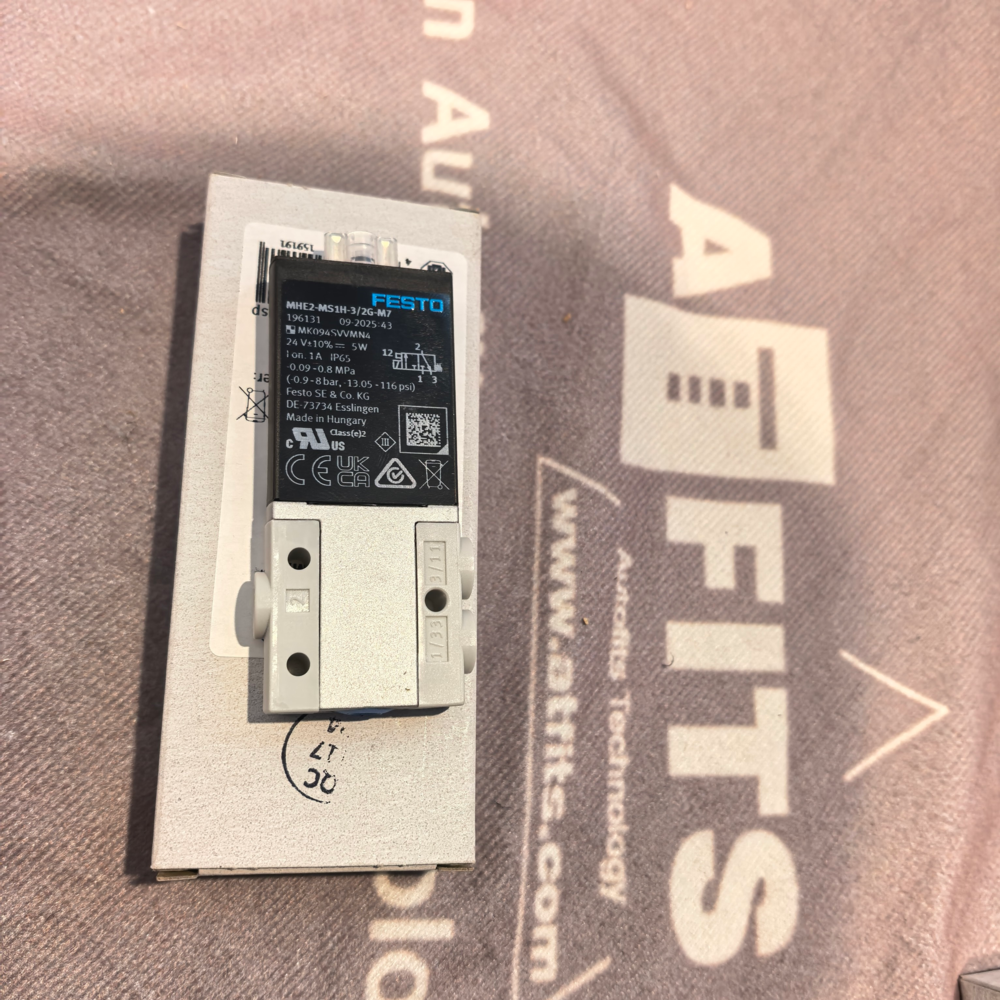

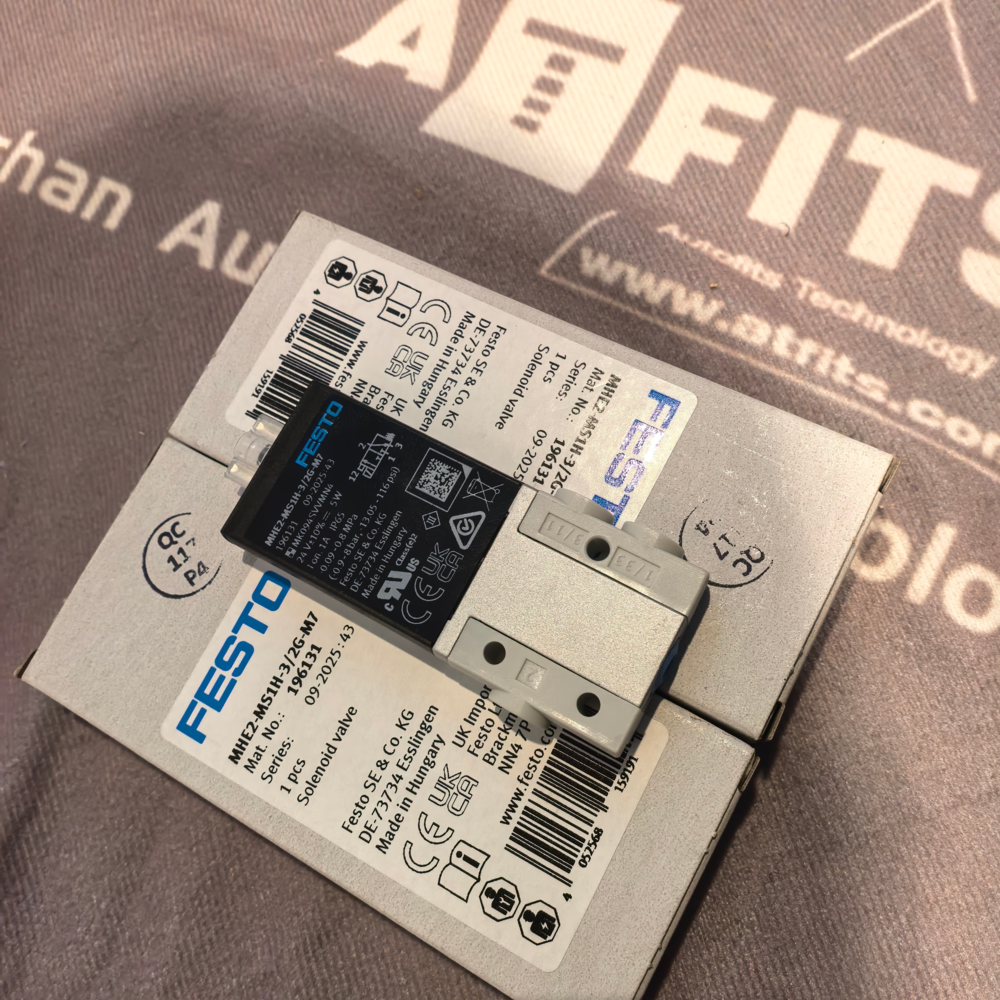

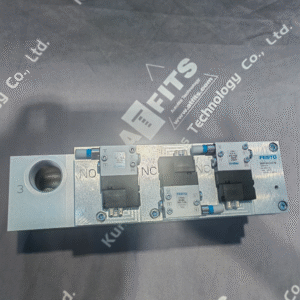

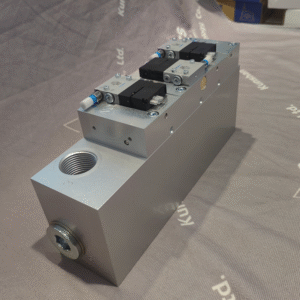

Festo MHE2-MS1H-3/2G-M7 Solenoid Valve (Order Number: 196131)

Product Overview

Main Functions

- 3/2-Way Normally Closed On/Off Control

The valve remains closed by default, blocking airflow from the inlet to the working port. When energized, the direct-acting solenoid lifts the poppet to connect the inlet and working port; de-energization triggers the internal spring to reset the valve, closing the flow path and venting the working port to exhaust for fail-safe operation费斯托.

- Vacuum and Low-Pressure Air Regulation

It efficiently controls vacuum (down to -0.9 bar) for workpiece holding and low-pressure air (up to 8 bar) for blowing or part ejection, eliminating the need for separate vacuum and pressure valves and simplifying system design费斯托.

- Ultra-Fast Switching for High-Cycle Tasks

With switching times below 2 ms and a maximum switching frequency of 330 Hz, it delivers rapid response for high-throughput applications like automated sorting lines and high-speed packaging machines.

- Manual Override for Commissioning and Maintenance

The non-detenting push-button manual override allows manual actuation without power, facilitating system setup, leak testing, and troubleshooting, ensuring operational continuity during electrical outages.

- Compact and Flexible Installation

The 10 mm width enables dense mounting on valve manifolds or directly onto equipment, while the M7 pneumatic ports and through-hole mounting simplify integration with minimal space requirements.

Technical Characteristics

| Technical Parameter | Specification |

|---|---|

| Valve Type | 3/2-way, normally closed, monostable |

| Actuation Method | Direct-acting electrical (solenoid) with spring return |

| Construction Width | 10 mm |

| Grid Dimension | 14 mm (minimum valve spacing: 4 mm) |

| Nominal Diameter | 2 mm |

| Standard Nominal Flow Rate (DIN 1343) | 100 l/min |

| Operating Pressure Range | -0.9 bar to 8 bar (-0.09 MPa to 0.8 MPa) |

| Maximum Switching Frequency | 330 Hz |

| Switching Times | Opening: 1.7 ms; Closing: 2 ms |

| Flow Direction | Limited reversible |

| Sealing Principle | Soft sealing (HNBR/NBR) |

| Exhaust Function | Throttleable |

| Manual Override | Non-detenting push-button |

| Protection Class | IP55 |

| Operating Voltage | 24 V DC (±10% tolerance) |

| Power Consumption | 5 W (inrush), 1.55 W (holding) |

| Duty Cycle | 100% continuous |

| Operating Medium | Compressed air (ISO 8573-1:2010 class 7); lubricated or non-lubricated |

| Operating Temperature | -5 °C to 60 °C |

| Storage Temperature | -20 °C to 60 °C |

| Approvals | cULus, RoHS |

| Housing Material | Die-cast zinc with coating |

| Sealing Material | HNBR/NBR |

Product Dimensions and Weight

| Parameter | Specification |

|---|---|

| Overall Length | 35 mm |

| Overall Width | 10 mm |

| Overall Height (including coil) | 52 mm |

| Pneumatic Port Type | M7 female thread (inlet, working, exhaust ports) |

| Electrical Connection | 2-pin connector (compatible with standard M8/M12 cables) |

| Mounting Hole Diameter | 3.5 mm |

| Mounting Hole Spacing | 14 mm (center-to-center) |

| Net Weight (valve body only) | 28 g |

| Net Weight (with standard coil) | 60 g |

| Gross Weight (with packaging) | 80 g |

Structural Highlights

- Pressure-Release Poppet Valve Design

The poppet valve with soft sealing ensures tight shutoff and minimal leakage, critical for maintaining vacuum integrity and pressure stability in precision systems. Its negative overlap design reduces switching delays, enhancing response speed.

- Direct-Acting Solenoid Actuation

No external pilot air is required, enabling reliable operation in vacuum environments and simplifying system architecture. The direct actuation also minimizes energy consumption and improves efficiency.

- Spring-Return Mechanism

The integrated spring provides consistent reset force, ensuring the valve returns to the closed position reliably when de-energized, preventing unintended airflow and enhancing operational safety费斯托.

- Compact and Durable Housing

The die-cast zinc housing with a protective coating offers high mechanical strength and corrosion resistance, while the 10 mm width allows dense mounting for space optimization in control cabinets and machine-mounted valve stations.

- Through-Hole Mounting

Pre-drilled through-holes facilitate quick and secure installation with standard fasteners, reducing setup time and ensuring stable positioning even in high-vibration industrial environments.

Sobre nosotros