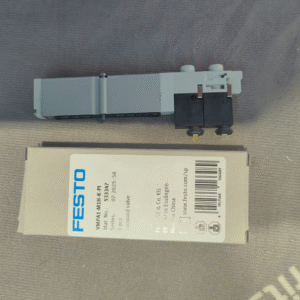

Festo EV-20/120-5 Clamping Module (Order Number: 13292)

Product Overview

Main Functions

- Single-Acting Clamping & Spring Reset

When supplied with compressed air (2–6 bar), the diaphragm drives the clamping plate downward to secure workpieces with a 5 mm strokeFesto. Upon air pressure release, an internal spring retracts the clamping plate to the initial position, enabling quick workpiece loading/unloading and fail-safe operation.

- Flat-Surface Workpiece Securing

The 20×120 mm rectangular clamping surface provides stable contact with flat workpieces, distributing clamping force evenly to prevent surface damage while ensuring firm grip during machining, assembly, or transportFesto.

- Space-Saving Installation

Its ultra-low-profile design and through-hole mounting allow integration into compact fixtures, tooling plates, or automated workstations where vertical space is limited, eliminating interference with surrounding componentsFesto.

- Consistent Clamping Force Output

Engineered for stable force delivery—up to 1000 N at 6 bar (maximum stroke)—it maintains reliable holding performance across repeated cycles, critical for process consistency in mass production.

- Copper-Free & PWIS-Free Compatibility

The copper-free construction avoids contamination risks in sensitive processes like battery manufacturing, while PWIS-free compliance ensures it meets strict standards for paint and wetting defect prevention in surface-critical applicationsFesto.

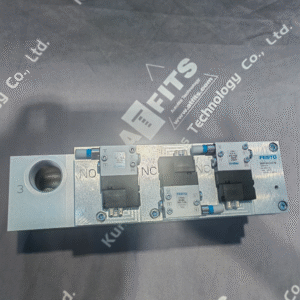

Technical Characteristics

| Technical Parameter | Specification |

|---|---|

| Module Type | Single-acting diaphragm clamping module (spring return) |

| Clamping Surface Dimensions | 20 mm × 120 mm |

| Stroke Length | 5 mm |

| Operating Pressure Range | 2 – 6 bar (0.2 – 0.6 MPa) |

| Maximum Clamping Force (6 bar, max stroke) | 1000 N |

| Operating Medium | Compressed air (ISO 8573-1:2010 [7:-:-]); lubricated or non-lubricated |

| Operating Temperature Range | -20 °C to 40 °C |

| Pneumatic Connection | M5 female thread |

| Mounting Type | Through-hole mounting |

| Housing Material | Die-cast aluminum |

| Diaphragm Material | TPE-U (thermoplastic polyurethane) |

| Corrosion Resistance | CRC 2 (medium corrosion resistance) |

| Compliance | VDMA24364-B1/B2-L (PWIS-free), RoHS, copper-free |

| Sealing Material | Nitrile butadiene rubber (NBR) |

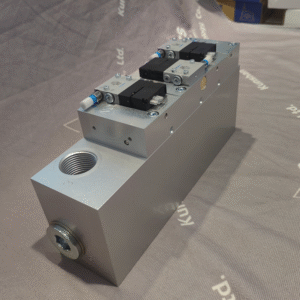

Product Dimensions and Weight

| Parameter | Specification |

|---|---|

| Overall Length | 120 mm |

| Overall Width | 20 mm |

| Overall Height (retracted) | 33 mm |

| Clamping Plate Thickness | 5 mm |

| Through-Hole Diameter | 4.5 mm |

| Through-Hole Spacing | 100 mm (center-to-center) |

| Net Weight | 190 g |

| Gross Weight (with packaging) | 250 g |

Structural Highlights

- Diaphragm-Driven Design

The TPE-U (PU) diaphragm ensures smooth, low-friction actuation with minimal wear, extending service life to over 5 million cycles under standard conditions. It also provides excellent airtightness, reducing leakage and energy wasteFesto.

- Die-Cast Aluminum Housing

The high-strength aluminum housing offers superior mechanical rigidity and corrosion resistance, while its flat profile allows flush mounting for seamless integration into fixture platesFesto.

- Internal Spring Reset Mechanism

The integrated spring delivers consistent reset force, eliminating the need for a separate return air supply and simplifying system design. It ensures reliable retraction even after prolonged use, preventing clamping plate jammingFesto.

- Through-Hole Mounting

Pre-drilled through-holes enable quick and secure installation with standard fasteners, reducing setup time and ensuring stable positioning during high-vibration operationsFesto.

- Copper-Free Construction

All components are free of copper (exceeding 5% by mass), making the module safe for use in lithium-ion battery production and other applications where copper contamination must be avoidedFesto

About us